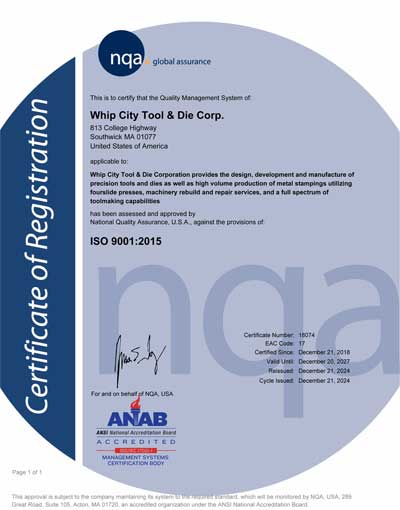

For over 50 years, Whip City Tool & Die Corporation has been known for quality, versatility, integrity, and personal service. Whip City Tool & Die Corporation understands every quality part begins with teamwork between our customers, suppliers and workers.

To ensure quality, Whip City Tool & Die Corporation has a vigorous inspection process; our employees follow written procedures and document inspections. To alleviate downtime, material is only purchased from approved suppliers who can meet our strict standards. From the time raw material enters our Shipping & Receiving Dept. quality carries through to final shipments. Boxes are barcode labeled for easy identification of part numbers, part revision numbers, quantities, customer order numbers and job numbers. In addition, all production parts are boxed, cornered and banded to pallets safeguarding fragile parts from damage during shipping. We are committed to continuous improvement through all aspects of business, including on-going education and training.

Whip City Tool & Die Corporation works closely with our customers, making every effort to fully understand their product. We take personal interest by traveling to our customers’ plants to ensure tooling, made by Whip City Tool & Die Corporation, produces only quality metal stampings.

It is interesting that tooling or metal stampings, made by Whip City Tool & Die Corporation, when assembled, make products that are used daily by consumers. The importance and seriousness of our work becomes apparent when looking around a room or driving in a car. Teamwork made all the intricate parts assemble to produce something spectacular. We take pride knowing that Whip City Tool & Die Corporation played a part.

History of Whip City Tool & Die Corp.

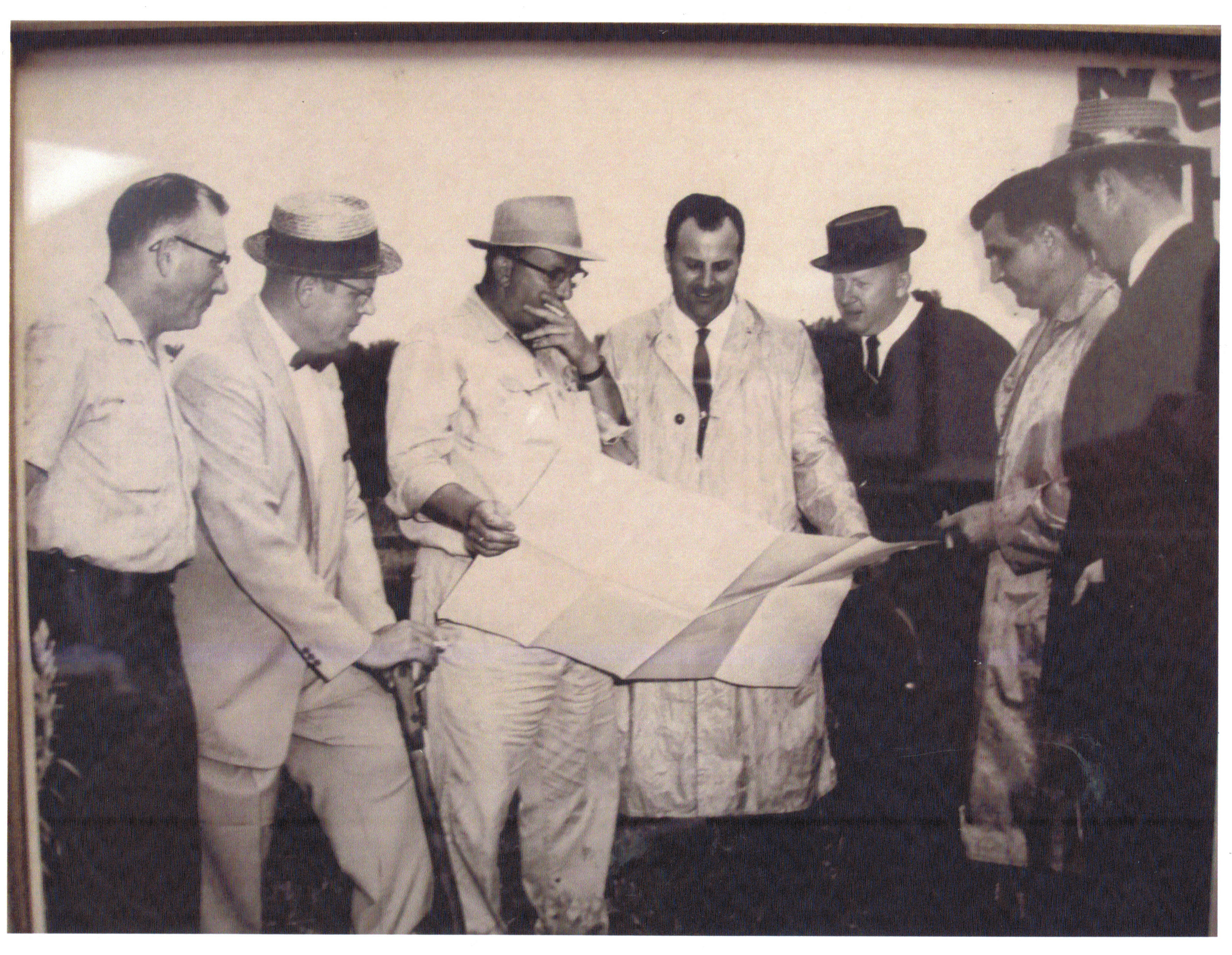

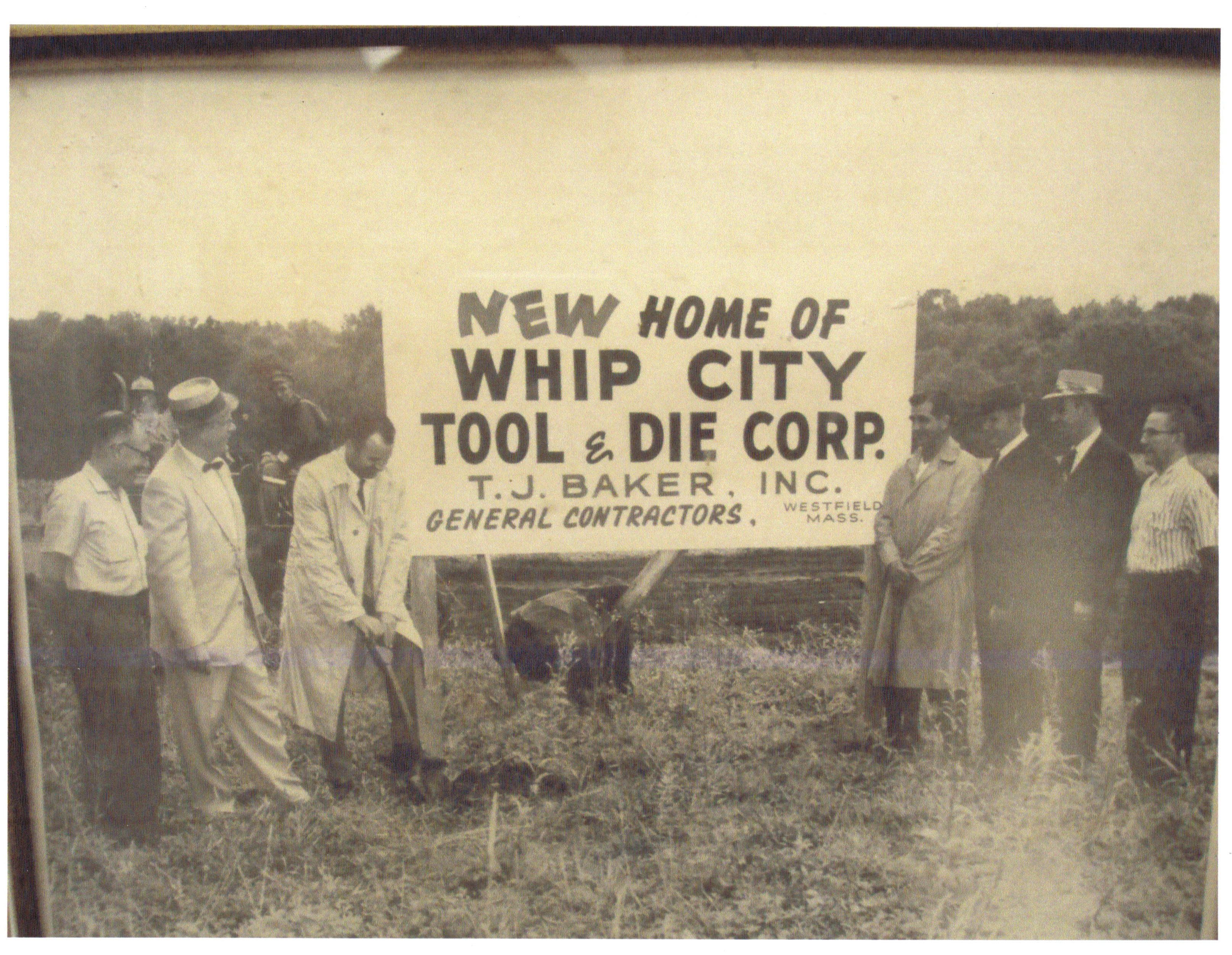

Whip City Tool & Die Corporation was started in 1957, by Henry Maclorowski, Luther “Red” Fisher and Bernard “Bernie” Jemilo in a small job shop in Westfield, Massachusetts (the Whip City).

Nicknamed the “Whip City”, because it led the nation in horse and buggy whip manufacturing in the early 19th century. To this day whips and horse tackle are still made in Westfield.

In 1960, the trio built a new 10,400 sq. ft. building and Whip City Tool & Die Corporation moved to Southwick, Massachusetts.

Whip City Tool & Die Corp. is located in the “Southwick Jog”. The town of Southwick, MA is known for its jog because part of its area dips into Connecticut resulting in an uneven line on the map between both states.

In 1960, the trio built a new 10,400 sq. ft. building and Whip City Tool & Die Corporation moved to Southwick, Massachusetts.

Whip City Tool & Die Corp. is located in the “Southwick Jog”. The town of Southwick, MA is known for its jog because part of its area dips into Connecticut resulting in an uneven line on the map between both states.

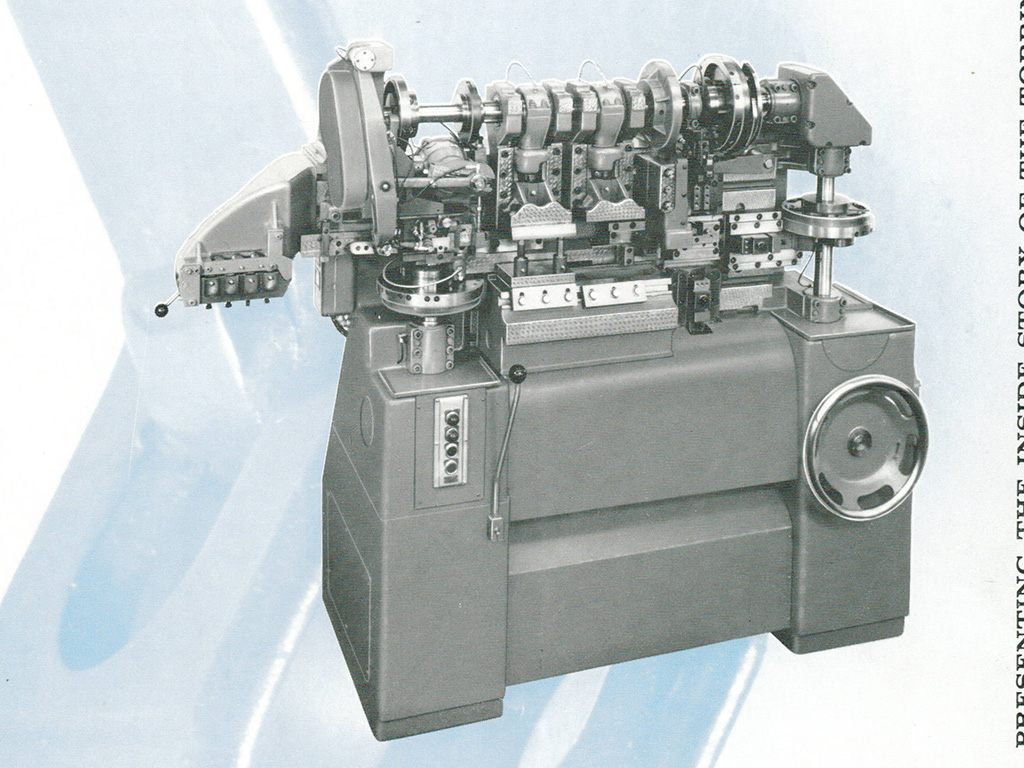

Traveling as far as Peking, China, Mexico, London, and throughout the United States with their Tooling and Vertislide Training.

Whip City Tool & Die Corporation became well known throughout the United States for its ability to design, build and set up tools for these vertical fourslide machines.

In 1984, Whip City Tool & Die Corporation was sold to three long-time employees; Raymond Salois, William Agan, and Jack Morpeth.

Whip City Tool & Die Corporation continued to support vocational education of future tradesmen through the Co-Op Apprenticeship Program with the Westfield Technical Academy.

45% of the staff at Whip City Tool & Die Corporation are trade school graduates.

Whip City Tool & Die Corporation continued to grow and several additions followed:

New Garage and Storage – 2000

New Tooling & Design Department – 2000/2001

New Shipping & Receiving Department – 2004

New Warehouse – 2010

Whip City Tool & Die Corporation now occupies a 17,500 square foot building with 2,400 square foot warehouse.

In January 2012, two long-time employees, Brian Iserman and Nathan Kane purchased Whip City Tool & Die Corporation from Raymond Salois.

In May 2022, Nathan Kane became sole owner of Whip City Tool & Die Corporation.

Whip City Tool & Die Corporation will continue the same traditions of quality parts, high level of service and support you have come to expect from us.